Research Project

Energy & Appliance Standards for Plug Loads: Assessing Current Needs and Future Opportunities

Research Team

Lead Researchers

- Bingbing Li, Manufacturing Systems Engineering*

- Kourosh Sedghisigarchi, Electrical and Computer Engineering

Collaborators

- Xunfei Jiang, Computer Science (CSUN)*

- Jose Dean, California Energy Alliance (CEA)*

- Joy Pixley, Calplug at University of California Irvine*

- Keith Graeber, CLTC at UC Davis*

Student Team

- Jianhao Zhu, BS Mechanical Engineering*

- Chenhao Wang, Mechanical Engineering

Funding

- Funding Agency: California Energy Commission (CEC)

- Funding Program: Advance Plug Load

Note: names marked with an asterisk (*) indicate current team

SYNOPSIS

- The California Energy Alliance (CEA) and California Energy Commission (CEC) are collaborating with CSUN to develop effective methods for optimizing energy consumption in laboratory equipment. This partnership aims to identify approaches that can improve the energy efficiency of lab operations.

- Due to the lack of existing measurement standards for laboratory equipment, CSUN has focused its research on creating energy consumption standards specifically for lab environments. The goal is to establish guidelines that will help reduce energy usage and support sustainable practices in laboratories.

Abstract

Plug loads are one of the fastest growing categories of energy use in residential and commercial buildings. Plug loads accounted for 40 percent of California residential electricity consumption and 27 percent of California commercial electricity consumption in 2018. With more and more devices being brought into and used in buildings, it is expected that the total energy use for plug loads will continue to increase. Plug load devices are typically not monitored nor controlled. Lack of effective, cost-effective appliance standards for these devices contributes to energy waste, greenhouse gas emissions and increased costs for business owners and consumers. The goal is to identify non-covered plug load devices with the most potential to inform future codes and standards (C&S) for energy efficiency or load management, and develop C&S recommendations and standardized test procedures to quantify their energy use for compliance purposes.

Plug loads are one of the fastest growing categories of energy use in residential and commercial buildings. Plug loads accounted for 40 percent of California residential electricity consumption and 27 percent of California commercial electricity consumption in 2018. With more and more devices being brought into and used in buildings, it is expected that the total energy use for plug loads will continue to increase. Plug load devices are typically not monitored nor controlled. Many of these devices have no power management capabilities and are powered continuously at full output. In addition, many of these plug loads are not regulated at the State or Federal level. Lack of effective, cost-effective appliance standards for these devices contributes to energy waste, greenhouse gas emissions and increased costs for business owners and consumers.

Research Team

Lead Researchers

- Bingbing Li, Manufacturing Systems Engineering

- Kourosh Sedghisigarchi, Electrical and Computer Engineering

Collaborators

- Xunfei Jiang, Computer Science

- Josh Dean, California Energy Alliance (CEA)

- Joy Pixley, Calplug at University of California Irvine

- Keith Graeber, CLTC at UC Davis

Student Team

- Chenhao Wang

- Jianhao Zhu, Mechanical Engineering

Funding

- Funding Agency: California Energy Commission (CEC)

- Funding Program: Advance Plug Load

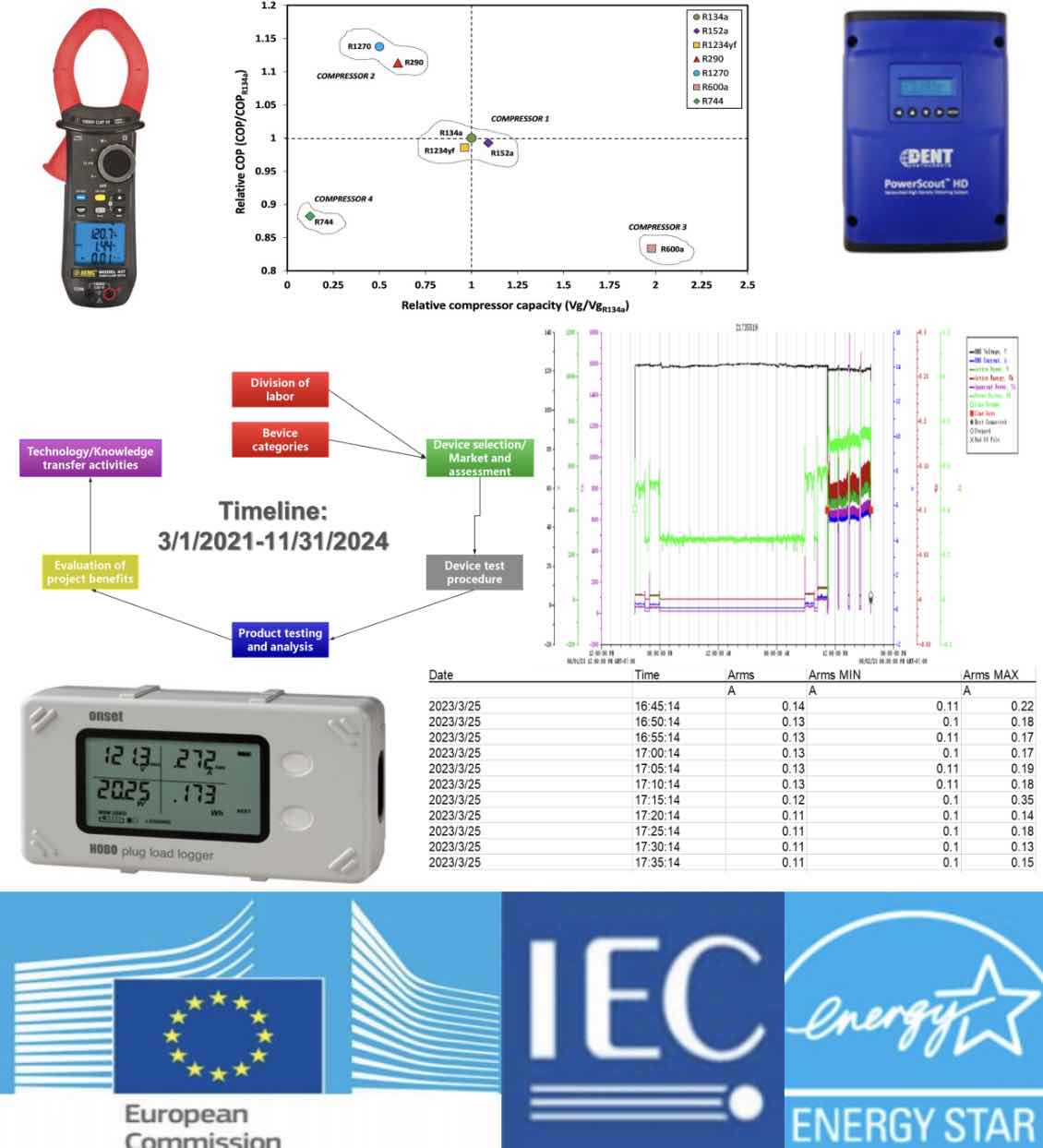

Alignment, Engagement and Contributions

The needs of standard & codes in Advance Plug Load from CA state.

Research Questions and Objectives

-

Benchmark Study: Identify plug load devices with the most potential for cost-effective energy savings.

-

Research Standards: Develop test procedures to reliably quantify energy use & related performance attributes for compliance purposes.

-

Methods: Test devices to determine energy consumption in active, standby, sleep, idle and/or other operating modes.

-

Data evaluation: Analyze test data and extrapolate results to determine specific C&S opportunities. Model the impact of the C&S recommendations to determine statewide savings and related impacts.

Research Methods

-

One of the most effective ways to reduce plug load energy use is through the adoption of device-level appliance energy standards.

-

In order to identify achievable energy savings opportunities, however, research must be completed to develop a market and manufacturing understanding of each unregulated device type, its subsystems, potential and existing operating modes, and its range of energy use and demand.

-

This will lead to new codes and standards opportunities for these plug load devices focused on such things as maximum power ratings, mandatory operational states (e.g., sleep or standby power use) and minimum component-level efficiencies.

-

In addition, future codes and standards will require specification of existing test procedures or development of new test or performance verification procedures to quantify energy use and, in the future, determine code compliance.

Research Deliverables and Products

Data obtained from laboratory freezers, water baths, incubators,

centrifuges and autoclaves show that:

-

Before the standard was established: Laboratory freezers, water baths, incubators, centrifuges and autoclaves did not have a specified energy stability standard.

-

After the standard was established: Based on limited data, laboratory freezers, water baths, incubators, and centrifuges have preliminary standards. The complex structure of the autoclave should be optimized according to its operating principle.

-

Future development direction: Since laboratory equipment is not included in the energy plan, it can be optimized according to the frequency of use and efficiency of its internal components.

Commercialization and/or Societal Impact Opportunities

-

Energy stability standard: After a large number of tests, it is convenient to further formulate detailed standards.

-

Academic purpose: Provide test methods and experimental data within limited data.

Research Timeline

3 year project 03/01/2021-03/31/2024

Research Team

Lead Researchers

- Bingbing Li, Manufacturing Systems Engineering*

- Kourosh Sedghisigarchi, Electrical and Computer Engineering

Collaborators

- Xunfei Jiang, Computer Science (CSUN)*

- Jose Dean, California Energy Alliance (CEA)*

- Joy Pixley, Calplug at University of California Irvine*

- Keith Graeber, CLTC at UC Davis*

Student Team

- Jianhao Zhu, BS Mechanical Engineering*

- Chenhao Wang, Mechanical Engineering

Funding

- Funding Agency: California Energy Commission (CEC)

- Funding Program: Advance Plug Load

Note: names marked with an asterisk (*) indicate current team