Research Project

Sustainable Manufacturing Alliance for Research and Training Industrial Assessment Center for Southern California

Abstract

Motivation/Research Problem

The objective is to assist small and medium-sized manufacturing facilities in reducing unnecessary costs due to inefficient energy consumption, as well as identifying ineffective production procedures, excessive waste production, and other production-related issues. The goal of the research is also to demonstrate cybersecurity awareness, smart technologies, and effective energy management systems. The student IAC team will work with small- and medium-sized manufacturers in identifying potential areas of annual energy savings opportunities and reducing annual costs.

Research Team

Lead Researchers

- Bingbing Li, Manufacturing Systems Engineering

Collaborators

- Dr. G.P. Li, Calit2 at University of California Irvine

- Dr. Li Zhao, Calit2 at University of California Irvine

- Dr. Kathleen Reiland, Cypress College

Student Team

- Jasmine Glover, Mechanical Engineering,

- Jason Kim, Mechanical Engineering

Funding

- Funding Agency: U.S. Department of Energy

- Funding Program: Industrial Assessment Center

Alignment, Engagement and Contributions

The U.S. Department of Energy with contribution and collaboration with the DOE IAC

Research Questions and Objectives

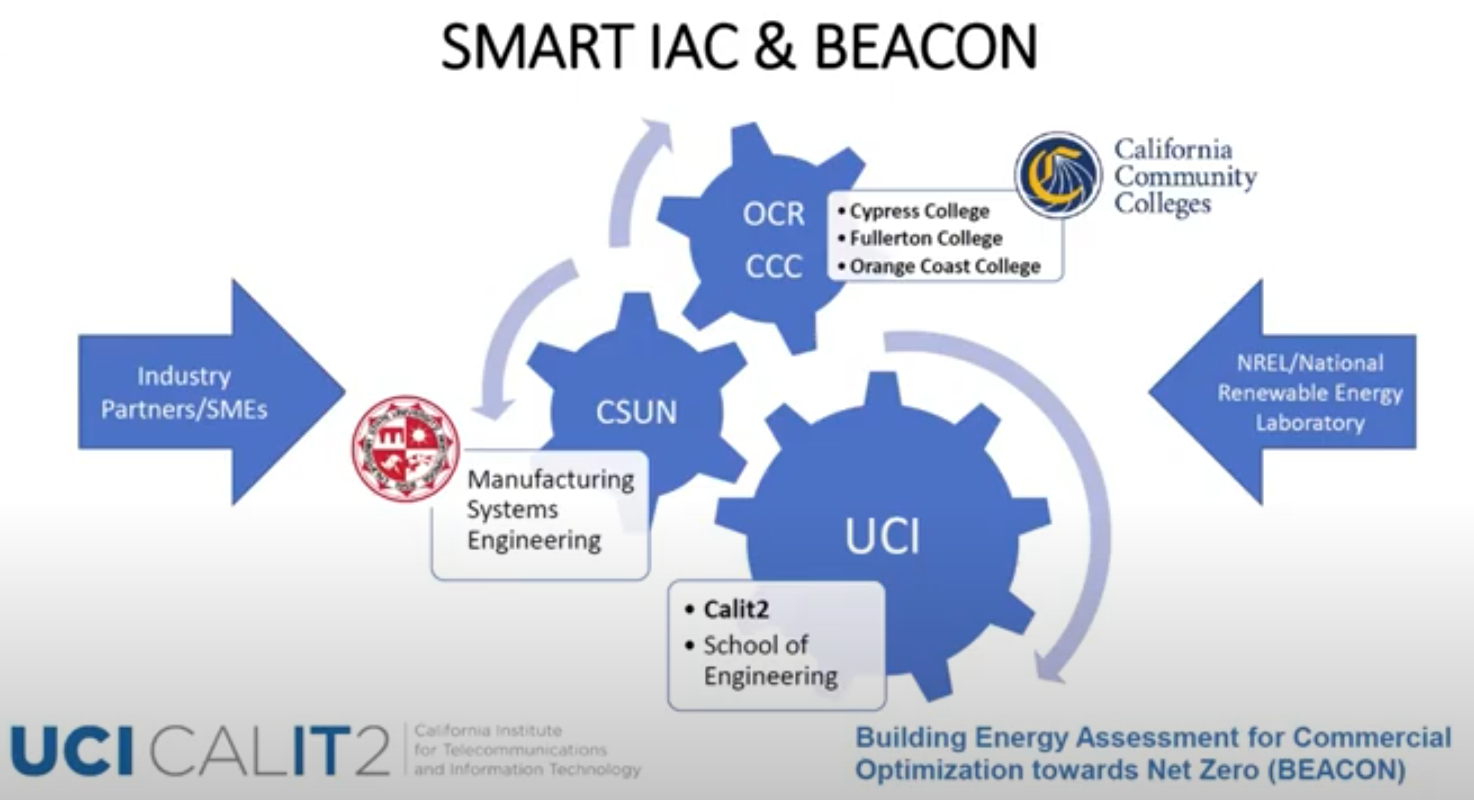

The SMART IAC will conduct at least 20 industrial sustainability (energy, water, health and safety) assessments per year while enrolling at least 10 students in the SMART IAC certificate program. By year two at least 5 students will earn a Certificate of Achievement in Industrial Assessment. The SMART IAC will establish a support center at Cypress Community College to establish a Commercial Building Efficiency assessment program to provide training to 5-10 students annually and conduct 10-20 commercial and/or other buildings each year. The SMART IAC will establish a Satellite Center at California State University Northridge (CSUN) to develop Life Cycle Analysis methods that can be incorporated into the sustainably assessments to be conducted for Topic 1 and Topic 2. In addition, the CSUN Satellite center will also develop broad based sustainability content for the SMART IAC curriculum. Students at all the affiliated institutions will be eligible for consideration in the SMART IAC industry sponsored internship program. All students will also be encouraged to participate in the SMART IAC Pueblo Fellowship program which is designed to provide students with leadership opportunities through which they can help to guide the direction of the SMART IAC with respect to operations and thematic focus. The proposed program will create a deep access and inclusion program to support the goals of producing diverse cohorts of Science Technology Engineering and Math professionals who have the knowledge and skills to effectively access sustainability in industrial contexts and to provide STEM leadership to address the challenges global climate change.

Research Methods

- Pre-Assessment Information Gathering: Client completes and submits a pre-assessment form.

- Ensure key plant personnel are involved:

• Plant manager

• Energy manager

• Environmental personnel

• Maintenance personnel - Pre-Assessment Analysis:

• Facility manufacturing processes and utility bills are analyzed;

• record primary energy systems, design and other technical documentations - Day of Assessment:

• Introduction

• Description of manufacturing process and operations

• Facility tour

• Debriefing

• Review notes

• Refine list of opportunities to be investigated

• Data gathering

• Exit interview - Post Assessment Activities:

• Engineering and financial analysis

• Compose IAC report

• Facility follow-up

Research Deliverables and Products

- IAC assessment report IAC certificate issued by DOE

Research Timeline

5 year project 09/2021–08/2026

Research Team

Lead Researchers

- Bingbing Li, Manufacturing Systems Engineering

Collaborators

- Dr. G.P. Li, Calit2 at University of California Irvine

- Dr. Li Zhao, Calit2 at University of California Irvine

- Dr. Kathleen Reiland, Cypress College

Student Team

- Jasmine Glover, Mechanical Engineering,

- Jason Kim, Mechanical Engineering

Funding

- Funding Agency: U.S. Department of Energy

- Funding Program: Industrial Assessment Center